Build Quality

Find out why the EuroFox is different to so many others

The EuroFOX build quality is of the highest standard with the materials used among the finest and most suitable for strength, longevity and reliability.

Aircraft Covering

All the EuroFOX flying surfaces are fully covered using the Stitts Polyfibre covering system. Medium grade fabric is used, rib stitched on the tail plane and elevator for additional security in the area of the propwash.

Our covering process ensures the EuroFOX is much more resistant to UV degradation compared to other forms of Dacron by means of vinyl sealers, followed by a vinyl Stitts Polyspray UV protective coating. This is applied prior to painting with a 2K plasticised paint by Dupont to the RAL colour of customer's choice. No Betts testing required for microlights.

The Wing

The wing is a beautiful two-spar aluminum design, with aircraft grade solid drawn aluminum spars and pressed aluminum full and half ribs, and aluminum wing tanks. Steel tube drag strut cross bracing with reinforced spar attachment points provide a wing of enormous strength. Glass fiber profile leading edge formers ensure clean airflow and the foam filled trailing edge adds stiffness. All aluminum is anodised for lifetime corrosion protection with the wing being a sealed for life unit.

The wing has 6 trailing edge mounts that support the Junkers flap and aileron system, so called flaperons. These flaperons provide fantastic light, and positive and powerful roll control of the aircraft. The flapperons have been significantly redesigned and repositioned in the airflow compared to other flapperon designs, to ensure that at full flap, full aileron control is available whilst landing in a cross wind - a common problem with some flapperon designs.

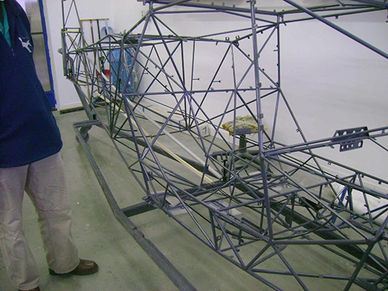

Fuselage, rudder, elevator and stabiliser

The fuselage and all flying structural parts are of a lattice design of 4130 Chrome Molybdenum steel tube, the bore of the tube is oil treated for long term corrosion protection. The tube exterior is painted with 2 coats of polyurethane 2K paint, manufactured by Dupont, for a long durable lifetime.

Undercarriage

The undercarriage is produced from glass reinforced plastic (GRP), offering tremendous strength (see 4.5 g landing above) with excellent damping on the roughest of surfaces. Proven by many years of hard work in the glider tugging environment, which is a much harsher life than training aircraft for example. The EuroFOX has one of the widest main wheel span's in its class at over 7'6", making landing a most enjoyable experience.

Other EuroFox quality features

Cowlings, wingtips, spats, seat pan - Glass reinforced plastic (GRP) or carbon fibre depending on model.

Engine frame - 5 point rubber mounted engine frame of 4130 Cr Mo steel tubing.

Nose wheel leg assembly - 4130 Chrome Molybdenum steel with rubber block damper for suspension and damping.

Controls - Aircraft grade aluminum pushrods with adjustable rose joint ends.

Panel - Aircraft grade aluminium panel, Dupont 2K painted. Options for laser cutting for instrument layout of choice.

Brakes - Berringer, with toe brakes on P1 as standard for tail wheel aircraft, P2 as an option.

More EuroFox quality features

Enclosed baggage bay - Aircraft grade aluminium sheet, formed individually for each aircraft, lined with Alcantara interior.

Fuel tanks - 2 x pressure tested 40 litre wing tanks in aluminium with 6 litre header tank fitted with low fuel warning sensor. (Option for 4 wing tanks and 160 litres). No need to switch tanks or suffer roll imbalance during flight.

Wheels - Aluminium split rim painted 2K paint.

Front screen, doors, cabane roof - Moulded acrylic (Perspex) front screen. Poly-carbonate sheet for doors and cabane.

Avionics - Radio and Transponder aluminium earthing plates secured to the fuselage prior to covering giving perfect transmissions.

Factory website www.aeropro.sk

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.